Environmental protection

As environmental impact is inherent in the PGNiG Group companies’ operations, their efforts are focused on managing work processes in an effective, efficient and environmentally friendly manner.

Environmental impact

The PGNiG Group’s operations affect the ecological balance. Both the production of natural gas and crude oil and their distribution interfere with the environment. On the other hand, the use of natural gas helps reduce atmospheric emissions more than other fossil fuels.

All companies of the PGNiG Group seek to minimise the negative impact of their operations. To that end, they follow the applicable Polish and EU laws, as well as internal standards and regulations. The implementation and certification of environmental management systems at most of the PGNiG branches and Group companies has delivered a number of notable environmental benefits. Our efforts are, in the first place, geared towards limiting our negative environmental impact and monitoring the processes on an ongoing basis. These rules are followed by the Group companies not only in their operations in Poland, but also in their exploration work abroad. Environment-oriented projects are undertaken across all areas of the PGNiG Group’s business – from hydrocarbon production to distribution to storage.

In addition, PGNiG strives to educate its employees in environmental protection, by organising training courses and conferences at which key issues related to environmental protection are discussed. Such courses and conferences are also aimed at defining a common range of tasks to be implemented in the future, primarily those relating to the CSR Strategy goals for the Group.

Well abandonment

Pursuant to the Polish Geological and Mining Law, PGNiG is required to properly plug and abandon depleted wells and extraction pits, eliminate the danger, remedy any damage caused by mineral extraction, and restore the land to its original condition.

The plugging of wells and pits prevents leakage of crude oil and natural gas to the surface and to water courses. Furthermore, if gas wells remain unplugged, there is a risk that escaping gas could accumulate, posing a fire hazard. In 2013, a total of 25 wells and 18 extraction pits were abandoned.

Land reclamation and evaluation of non-producing assets

Pursuant to the Environmental Protection Law, PGNiG conducts evaluation and land reclamation work in areas which have become polluted in the course of its earlier operations (including those related to traditional gas production), with a view to restoring them to condition prescribed by environmental quality standards.

In 2013, the Company carried out reclamation work on properties with a total area of 665 m2 in Kargowa, Radków and Łabiszyn, and commenced reclamation work on a property in Warsaw. The land reclamation work involves decommissioning of tar tanks and removal of local soil contamination (most often found near the tanks) through their extraction and neutralisation by operators contracted by the Company.

In 2013, work was performed to analyse the soil environment of a property in Działdowo.

PGNiG also monitored the soil-water environment of the reclaimed landfill site in Zabrze-Biskupice, and a property in Zabrze.

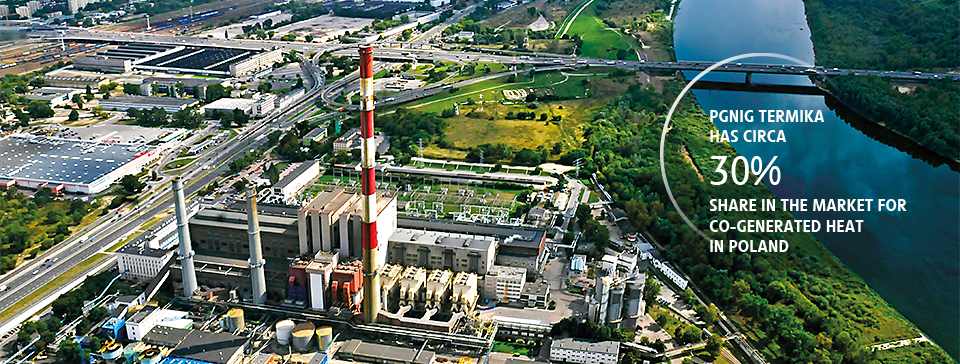

Carbon emissions trading scheme

In 2013, CO2 emissions from our facilities covered by the CO2 emissions trading scheme (EU ETS) reached 6,082,799 Mg. In this trading period, installations covered by the scheme included PGNiG TERMIKA SA (the Siekierki, Żerań and Pruszków CHP plants and the Kawęczyn and Wola heating plants), the Zielona Góra Branch and the Odolanów Branch, the Mogilno Underground Gas Storage Cavern Facility and the LMG oil and gas production facility.

CO2 emissions [Mg] in 2013

| Facility name | National Allocation Plan No. | Emission allowances [Mg] |

Actual emissions in 2013 [Mg] |

Remaining amount [Mg] |

|---|---|---|---|---|

| Mogilno Underground Gas Storage Cavern Facility | PL-898-08 | 8,532 | 5,354 | 3,179 |

| PGNiG Odolanów Branch | PL-562-05 | 8,589 | 11,607 | –3,018 |

| PGNiG Odolanów Branch | PL-950-08 | 21,760 | 25,885 | –4,125 |

| LMG Oil and Gas Production Facility | PL-1070-13 | 0,000 | 14,381 | –14,381 |

| PGNiG Zielona Góra Branch, Dębno Oil and Gas Production Facility | PL-563-05 | 22,244 | 27,734 | –5,490 |

| Total | 61,125 | 84,961 | –23,836 |

Use of chemicals under EU requirements

In 2013, in accordance with the regulations of the European Parliament and of the Council (EC) on safe use of chemicals (REACH) and on the classification, labelling and packaging of substances and mixtures (CLP), PGNiG supervised compliance with these regulations by its subcontractors using chemical substances for well treatments.

The Company also drew up contractual provisions, to be included in its hydraulic fracturing agreements, concerning the use of chemical substances and mixtures to facilitate the control of related hazards and ensure compliance with all requirements imposed by Polish and EU laws.

Environmental Management System

The Environmental Management System operates on the basis of significant environmental aspects, which directly affect other elements of the system – environmental policy, tasks and objectives, monitoring and measurement, as well as operational control.

Most PGNiG companies have implemented, certificated and maintain the PN-EN ISO 14001-based Environmental Management System (EMS), which is frequently integrated with other systems, such as quality assurance, OHS and information security management systems. The remaining companies have begun preparations to implement a system-based management model.

In 2013, PGNiG completed the first stage of the implementation of an Environmental Management System at its trading divisions. As part of the work, an environmental review was performed.

Environmental Management Systems in the PGNiG Group

Nature 2000

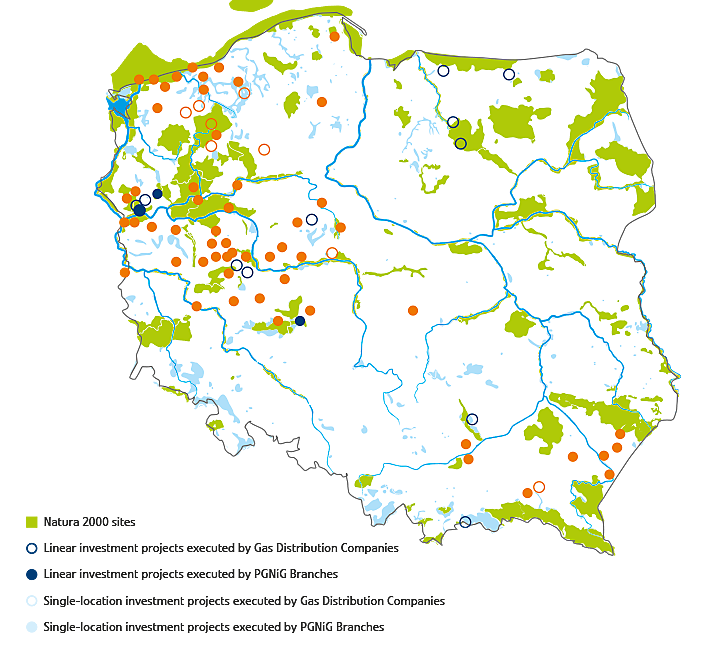

When selecting a site for a project, we take into consideration the presence of any protected areas, Natura 2000 sites or other areas of high environmental value, which, on one hand, require special procedures during the execution phase or compensatory measures, and, on the other hand, may constrain our plans.

When undertaking an investment project, companies of the PGNiG Group act in compliance with relevant regulations and strive to minimise the project’s impact on the environment and on protected species and habitats within Natura 2000 sites. If it is required under applicable regulations or by the authority qualified to issue a decision on environmental conditions, before the commencement of a project, a report on the assessment of its impact on the environment and the Natura 2000 site is prepared.

Thanks to advanced technological solutions and mitigation measures, we can execute projects within Natura 2000 sites or in their vicinity without any adverse impact on the species and habitats protected there.

Investment projects of the PGNiG Group in protected areas

Biomass supplies

In an effort to fulfil the requirements of Directive 2009/28/EC on the promotion of the use of energy from renewable sources and use of biomass other than forest biomass, that is biomass from plantations and energy plant crops at commercial power plants (Regulation of the Minister of Economy dated October 18th 2012), PGNiG TERMIKA SA procures fuel under long-term contracts for the supply of biomass from energy willow plantations. Currently, the company procures biomass from plantations with a total area of ca. 386 ha. Thanks to the use of biomass as a fuel, in 2013 CO2 emissions were reduced by 104,834 Mg.