Power Generation

On the path to achieving a major strategic goal of growing its power business, the PGNiG Group continues to embark on new projects, both large and small, involving construction of new gas-fired capacity.

On January 11th 2012, the Group finalised the purchase of Vattenfall Heat Poland’s (VHP’s) assets. Following the transaction, its total installed heat and power generating capacity has grown to 4,804 MWt and 995 MWe, respectively. The acquisition has also given the Group an approximately 3% share in the domestic power generation market and an approximately 30% share in the market for co-generated heat. The CCGT project implemented jointly with the TAURON Group in Stalowa Wola (PGNiG holds 50% of the 450 MW capacity), the acquisition of VHP assets, and a range of new projects to build gas-fired capacity will facilitate attaining the target of 1,300 MWe generating capacity by 2015. Investments in the power generation sector will boost demand for natural gas and will perfectly match the PGNiG Group’s mission which is to develop and increase company value in line with the principles of sustainable development and with due consideration for the natural environmental.

Key Events in 2012

- On January 11th 2012, PGNiG completed the purchase of 99.8% of shares in Vattenfall Heat Poland SA.

- On April 26th 2012, a contract was signed with the general contractor for the Stalowa Wola unit, with the contract price totalling PLN 1.57 bn. The project, involving the construction and future operation of a 449.16 MW gas-fired CHP plant, is being carried out jointly by the PGNiG Group and the TAURON Group via special purpose vehicle Elektrociepłownia Stalowa Wola.

- On October 4th 2012, PGNiG Termika was merged with PGNiG SPV1. The former assumed all rights and obligations of PGNiG SPV1.

- December 3rd 2012 was the start date of construction of the 449.16 MW CCGT unit in Stalowa Wola. The project is to be completed at the end of 2014 or beginning of 2015. The CHP plant will be placed in commercial operation at the end of the second quarter of 2015.

PGNiG Termika SA

The merger of PGNiG Termika and PGNiG SPV1 crowned the process of acquiring Vattenfall Heat Poland’s generation assets in Warsaw. The merger plan was approved by the Supervisory Board resolution of October 4th 2012, and the process was finalised late in December 2012. The transaction implements the strategic objective of making PGNiG Termika a competence centre for the Group’s power generation business. PGNiG SPV1 is a special purpose vehicle established to acquire shares in Vattenfall Heat Poland by PGNiG SA. The acquisition of Vattenfall Heat Poland SA’s heat and power generation assets was well received by the market – in addition to other factors, it was that transaction that prompted Standard & Poor’s Financial Services to upgrade PGNiG’s outlook in recognition of the benefits related to greater diversification and enhanced business risk profile.

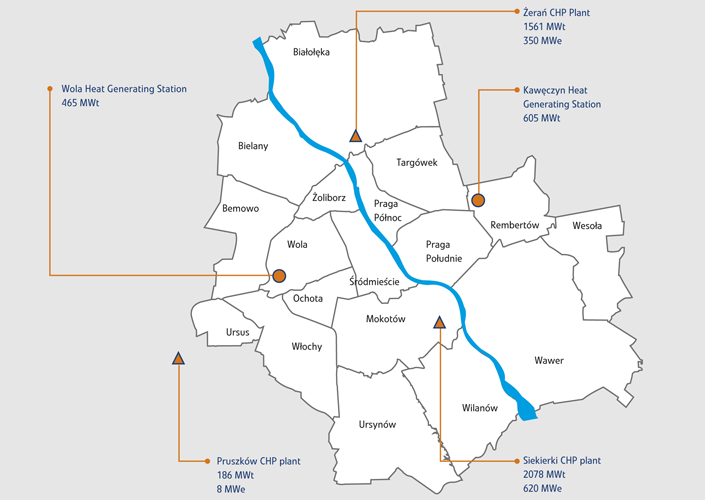

PGNiG TERMIKA’s assets in Warsaw

PGNIG Termika has become the Group’s competence centre for power generation. Experienced staff will support continued expansion in the power generation market, with the company’s efforts reaching beyond the local heat market in Warsaw and being used to further new Group heat and power projects across Poland.

The total generation capacity of heat and power stations owned by PGNiG Termika represents over 23% of the total installed heat generation capacity in Poland. The annual average heat and power sales amount to 39.7 TJ and 3.7 GWh, respectively. The two largest assets are the Siekierki and Żerań CHP stations. The company also owns heat generating plants in the Kawęczyn, Wola and Regaty districts, and a CHP plant and heating network in Pruszków and its vicinity. PGNiG Termika’s heat covers approximately 75% of demand in Warsaw, and represents 97% of the heat supplied to Dalkia Warszawa’s network.

Capex projects

Capital expenditure incurred in 2012 at PGNiG Termika amounted to PLN 286 m. Major capex projects included those related to flue gas desulphurisation and denitrification (deSox and deNox) technologies. 2012 saw the completion of the second stage of the wet flue gas desulphurisation project at the Siekierki CHP plant.

In 2010, a flue gas deNox project was launched at the Siekierki CHP plant, with a four-stage work schedule to be executed between 2010 and 2014.

CCGT unit at Żerań CHP plant

Following completion, the CCGT project will contribute to upgrading the Żerań CHP plant in Warsaw. The worn-out coal-fired boilers will be retired, and the new unit will allow the plant to increase power output by 50%. The unit, with an installed capacity of around 450 MWe, will consume over 650 m m³ of natural gas every year. The plant will be put into operation in 2018. The unit’s technical parameters will meet the requirements of the Industrial Emissions Directive (IED) and the BAT (Best Available Techniques) standards. The project will also contribute to power security in the Warsaw metropolitan area and to further improvement in air quality.

In Q3 2012, relevant environmental permits were secured and a contract was signed with ILF Consulting Engineers Polska for the provision of preparatory services for the construction of a high-pressure gas pipeline to the Żerań CHP plant. In Q4 2012, an agreement was signed to connect the Żerań CHP plant to the OSP Gaz-System SA transmission network, and later an application was filed to connect the plant to PSE Operator SA’s transmission network.

New Pruszków CHP Plant

In June 2012, a conceptual design for an upgrade of the Pruszków CHP plant was selected. The modernisation will involve construction of a new generating unit powered by gas engines with a total capacity of approximately 16 MWe and 15 MWt, as well as modernisation of the existing WR-25 hot water boilers, all of which will ensure compliance with tighter environmental standards in the future. The design also provides for construction of a new peak and standby boiler house fired by natural gas or light fuel oil. In November 2012, an application was submitted to the Mazovian Gas Distribution Company to issue a decision specifying the terms of connection to the gas network.

Combined Cycle Gas Turbine in Stalowa Wola

On April 26th 2012, a contract was signed with Abener of Spain (general contractor) for construction of the CCGT unit in Stalowa Wola. The unit will be the largest of its kind in Poland. The project, for construction and future operation of a 449.16 MW gas-fired CHP plant, is being carried out jointly by the PGNiG Group and the TAURON Group, each holding a 50% interest. The CHP plant will produce heat in the form of hot water for the town’s residents and process steam for industrial facilities located nearby. The agreement between the project partners provides that revenue from sales of electricity will be shared pro rata to their interests in the Stalowa Wola CHP plant. It is estimated that the Stalowa Wola unit will generate approximately 3,500 GWh of electricity per year, while burning approximately 600 m m³ of gas . The unit will generate low carbon dioxide, SOx and NOx emissions, in line with the EU’s energy and climate policy. The project is to be completed at the end of 2014 or beginning of 2015. The CHP plant will be placed in commercial operation at the end of the second quarter of 2015.